top of page

Technology / R&D

Leading Edge Technology

Received the Minister of Japanese Ministryof Economy, Trade Trade and Industry Award at the Monodzukuri Japan Grand Prize (Manufacturing Award)

Copper plating characteristics

Our copper plating characteristics

・Proton Accelerator needs electrical large power. Our copper plating with high purity copper degree is superior on the ability to conduct electricity than others.

・Save energy and reduce radioactive contaminated water.

・Reach the targetted vacuum level soon.

Accelerators are used for the study of investigating origin of the universe etc. Conventional accelerators had adopted copper plating which contains organic substances that create extra gas under vacuumed air condition. It caused problem that it takes long time to draw a vacuum and so on.Therefore, our copper plating technology was took up to solve them. We devised anoxia copper plating which is free of brightener chemical. Then, we have been performing copper plating to evironmentally friendly proton accelerators.

* Received the Minister of Japanese Ministryof Economy, Trade Trade and Industry Award at the Monodzukuri Japan Grand Prize (Manufacturing Award)

1/3

Reserach and Development

"Asahi Kinzoku Kogyo Inc." is working on R & D project supported by Japanese government agencies. We will aim to contribute society and technique through it.

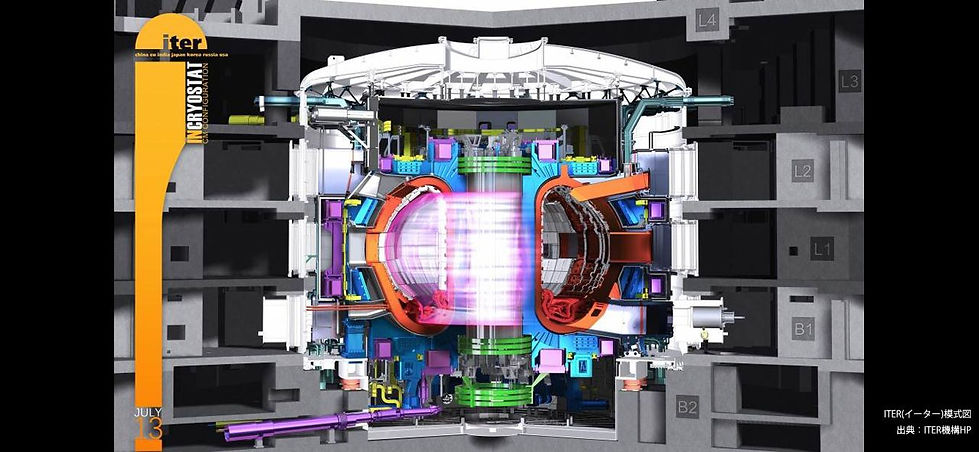

ITER(International Thermonuclear Experimental Reactor)

Our copper plating technology is used for coolying system. It helps reducing enerygy problem and CO2. *Supported by National Institutes for Quantum Science and Technology

Credit@ITER OrganizaDon,http://www.iter.org/

Thermoplastic Compposite Material(PEKK)

In order to satisfy with the demand for lighter weight airplanes, non-metal parts are increasing, therefore, we are researching and manufacturing composites as prototype parts. Our composites accomplishes compressing time of productions and high quality characteristics with cutting-edge manufacturing method compared to previous way.

*New Energy and Industrial Technology Development Organization, Jointly developed with Takagi Seiko Corporation

Our Thermoplastic Compposite Material(PEKK) characteristics

・Heat-resistant

・Fire-resistant

・Chemical-resistant

・Toxic gas free

・Half weight of Aluminum

・Less lead time

(conventional method: 6min→Our Method:3min)

・Cost competitive

Use as;

Interior, Exterior, Structure etc.

Credit@ITER OrganizaDon,http://www.iter.org/

1/3

bottom of page